Instrumentboard Check – Checksystem by L&_P GmbH

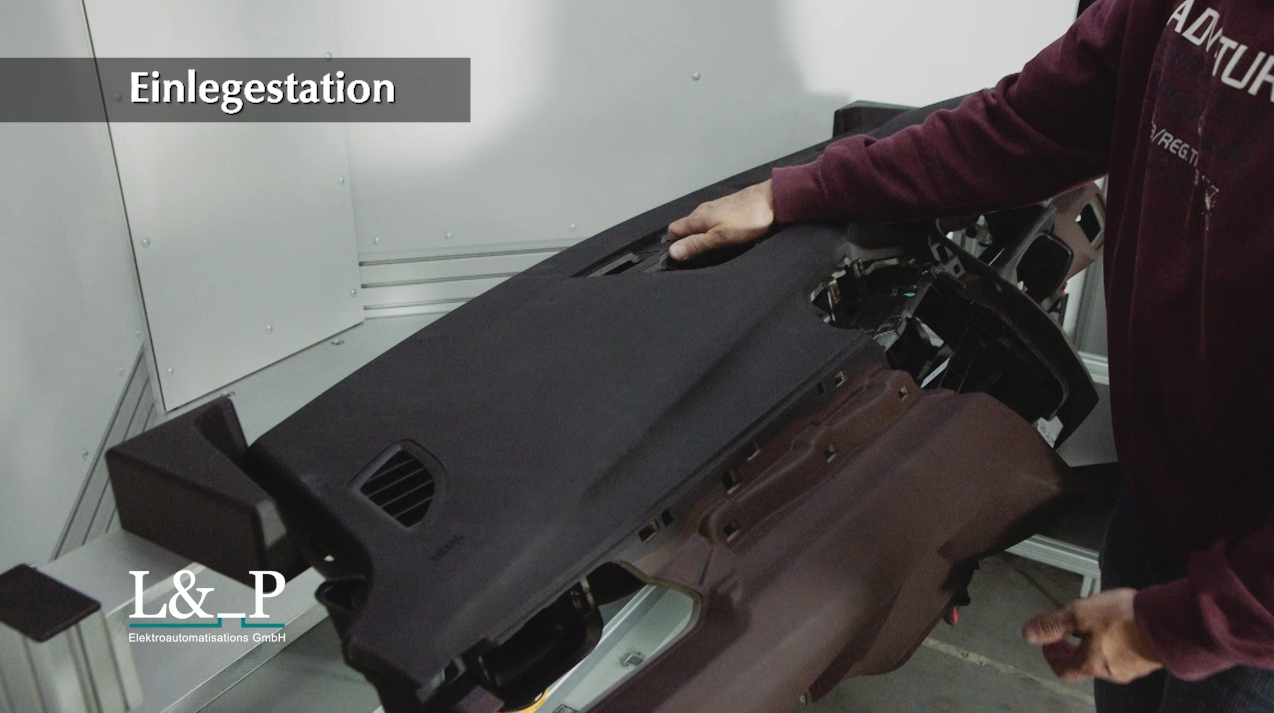

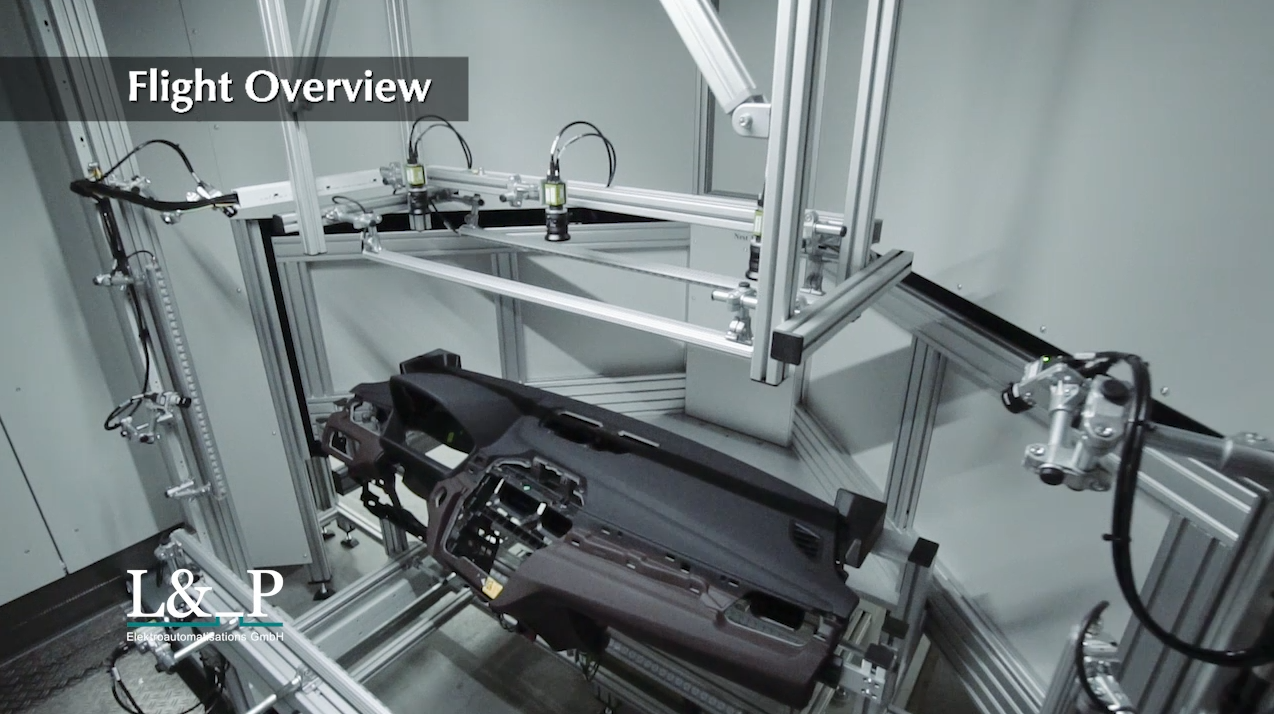

The test systems are built as independent, functional systems. The assemblies (for example, interior doors, i-panels, bumper, side panels, etc.) are inserted manually or vertically into the contour-accurate photographs with the visible side (A-side). A glued-on broadcast code is read by means of scanners and the test sequence stored for this module variant is started. The assembly then moves to the visual inspection station (s) and is checked there. After completion of the test, the assembly moves to the removal station and the results are compiled and displayed. In an i.O. A “green message” is output and the operator can remove the module. In a n.i.O. The errors are displayed, a “red message” is output and the further procedure is determined by the operator. The entire system is operated and monitored via the TFT monitor (s) on the loading and / or removal side.

Due to the use of our test systems, the manual test activity should be dispensed with up to approx. 100%.

The test system is operated via TFT touchscreen screens on the loading and / or removal side. The label of the interface is in German and has a language switch. Only the visible surface labels are adapted. The operation is easy to understand and easy to carry out. The user interfaces can be discussed with you in detail and adapted to our standard designs.

A user-friendly interface is used to set up the individual modules, which allows the configuration without special image processing knowledge.

The test system supports the operator (if necessary) interactively by setting up a new test item by means of a type management. The user software is designed in such a way that, after inserting the module, the broadcast code is first read, by means of which the module variant is determined. Using this information, the user software then automatically builds up the test sequence with the stored parameters and starts the test routine. All stored values are determined and these stored after expiration into a file. Data can be linked via a traceability system.